Loads - Joint Load / Displacement

You may specify joint loads,

and enforced joint displacements and joint

mass in any of the global degrees of freedom. Loads and displacements

may be applied in any non-global direction by defining components of the

load in the global directions. This may be accomplished graphically

or in the spreadsheets. See Drawing Joint Loads below to learn how

to apply joint loads/displacements/masses

graphically.

Drawing Joint Loads

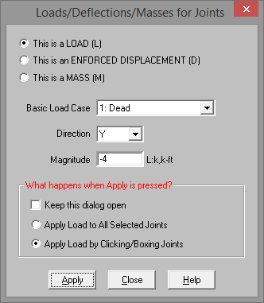

You can apply joint loads to joints. You

must enter the load direction, magnitude and type. Make sure that

you are careful to enter the correct BLC number that you want the loads

assigned to. See Joint Load/Displacement above for more information

on joint loads.

- If

there is not a model view already open then click

on the RISA Toolbar to open a new view

and click

on the RISA Toolbar to open a new view

and click  to turn on the Drawing

Toolbar if it is not already displayed.

to turn on the Drawing

Toolbar if it is not already displayed.

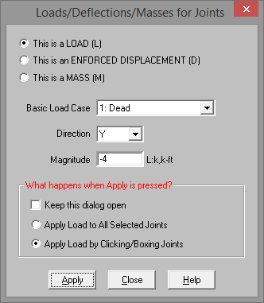

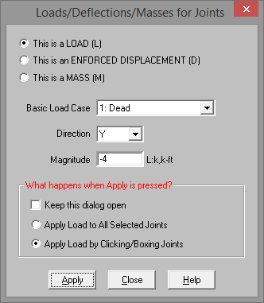

- Click

the Apply Joint Loads

button and

define the load. For help on an item, click

button and

define the load. For help on an item, click  and then click the item.

and then click the item.

- You

may apply the load by choosing jointson the fly or apply it to a selection

of joints.

To choose joints

on the fly choose Apply by Clicking/Boxing Joints and click/box on the joints with the left mouse button.

To apply the

load to a selection, choose Apply Entries to All Selected Items.

- To apply more loads

with different parameters, press CTRL-D to recall the Joint Loads

settings.

- You may also specify

or edit joint loads/displacements in the Joint Loads Spreadsheet.

- You may undo any

mistakes by clicking the Undo

button.

button.

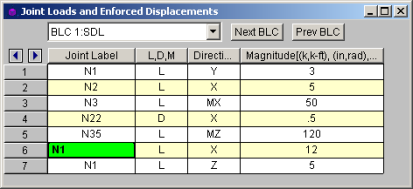

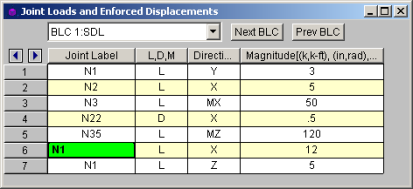

Joint Load Spreadsheet

The Joint Load Spreadsheet

records the loads for the joints and may be accessed by selecting Loads

Joint Loads on the Spreadsheets menu.

Joint Loads on the Spreadsheets menu.

When you open this spreadsheet you

may view only one basic load case at a time. Use the drop down list

on the toolbar to specify a different load case. The current load

case is also displayed in the title bar at the top of the spreadsheet.

The Joint Label specifies the joint

that receives the load or displacement. The same joint may be listed

any number of times.

The next column indicates the value

is a load or an enforced displacement. Enter "L" if it’s

a load, "D" if it's a displacement and

“M” if it is a mass.

The direction code indicates in which

of the global directions the value is applied. Valid entries are

X or Y for the translational directions, or MZ for the rotational direction.

The Magnitude column holds the value of

the load, displacement or mass. The appropriate units for the magnitudes

are displayed at the top of the column. Which units apply depends

upon whether the value is a load, displacement or mass, and whether the

direction is translational or rotational.

- If

you have a “Reaction” or a “Spring” boundary condition for the same degree

of freedom that you have an enforced displacement assigned, NO reaction

will be calculated. See Reactions

at Joints with Enforced Displacements to learn how work around this

limitation.

Joint Mass

For more sophisticated dynamics modeling, you can

enter your mass directly as a mass rather than have the program convert

it from a load. Using joint masses offers several advantages such

as being able to define directional mass and also the ability to specify

mass moment of inertia’s to account for rotational inertial effects.

The units used for Joint Mass are derived from the current Force

and Length units as specified on the Units settings.

For example, if the current force units are Kips and the current length

units are Feet, you will need to specify your mass as kips / g and mass

moments of inertia as kip-ft2

/ g where g is the acceleration of gravity given in those units (feet

per seconds squared).

When specifying a joint mass on the Joint Loads spreadsheet,

enter an “M” for the load type. The directions are defined

relative to the global axes. Enter translational mass using the

global X, Y, or Z codes and mass moments of inertia

by specifying the global MX, MY or MZ.

Joint masses only allow dynamic response in the direction that they’ve

been applied. This can be a very effective way to prevent local

modes. A good example is a floor diaphragm modeled with plate/shell

finite elements. If the mass is only specified for the two lateral

directions, you will prevent any unwanted vertical modes. Care must

be taken in limiting dynamic response using directional mass for complicated

structures. A structure that has “coupled modes” will not give the

“real” dynamic response when mass is only specified in one or two directions.

A coupled mode is a mode that has mass participate in two or three directions

at one time.

Joint masses also allow you to account for rotational inertia effects

by specifying a mass moment of inertia. These are particularly important

when you’re using a rigid diaphragm and you’ve also lumped all your mass

at one point (typically the center of mass). The rotational inertia

effects contribute to the torsion on the diaphragm and should not be neglected.

The following table shows some typical diaphragm shapes and the formulas

to calculate their mass moment of inertias. Note that you can use

the axis transformation equation to calculate the mass moment of inertia

for diaphragms that are combinations of these basic shapes. For

very irregular diaphragms, a more general equation is given based on the

in-plane moment of inertia and the area of the diaphragm.

Mass Moment of Inertia About

an Axis Through the Center of Mass

In the table below C.M. is the center of mass point.

M is the total Mass of the area (typically including self weight, dead

load, and a percentage of the live load) and is assumed to be uniformly

distributed throughout. Ixx is the moment of inertia about the X-X

axis. Izz is the moment of inertia about the Z-Z axis. A is

the area. MMIo is the mass moment of inertia about some other point.

| Area Plan View |

Formula |

|

|

M (b2 + d2) / 12

|

|

|

M d2 / 8

|

|

|

M (Ixx + Izz) / A

|

|

|

MMIo + M D2

|

button.

button.![]() Joint Loads on the Spreadsheets menu.

Joint Loads on the Spreadsheets menu.